SAP for Oil and Gas

SAP for Oil & Gas Industry optimizes the production and delivery of oil and gas. You can connect workers, suppliers, and customers on a digital energy network with SAP for Oil & Gas to simplify operations, enhance efficiencies, and achieve new levels of safety, cost control, and agility to survive in challenging markets.

SAP Oil & Gas Industry helps companies optimize capital expenditures, increase asset returns, and increase profitability while maintaining safe and sustainable operations. Drilling and well servicing are two activities that oil and gas operating firms use to provide the globe with reliable access to energy sources.

Companies in the OFS sector develop innovative equipment and services, increase asset utilization, boost profitability, and run efficient operations all while operating securely, efficiently developing people, and continuously reinventing their organizations.

SAP Oil and Gas Industry offers solutions for everything from project management to hydrocarbon production and management. Whether you specialize in well-servicing, offshore drilling, equipment manufacturing, or transportation, you can deliver world-class, profitable oil field services. From product design and safety to supply chain management and shipping, support your end-to-end processes.

SAP Implementation for Oil & Gas Industry

SAP Implementation is important for Oil & Gas Industries to sustain overall functioning activities while adhering to best practices and standards. It aids in the management of total functional operations in order to achieve operational excellence.

Oil and gas businesses supply products to meet rising energy demands and market problems, governed by massive expenditures in upstream and downstream oil and gas product manufacture. Customers demand products such as crude oil, petroleum products, oil tankers, natural gas, and so on.

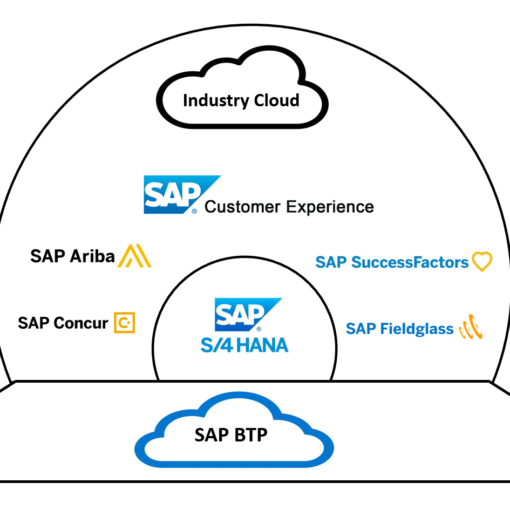

SAP S/4HANA for Oil & Gas Industry

Global energy demand is expected to increase by 50% by 2030. With an active increase in Natural Gas contribution, the oil and gas industry would operate as an unavoidable supply of energy.

With gas being a critical energy source in both production and demand in many cities, we must rely on cost-effective solutions. It should not arouse the desire for long, tedious processes that stifle development. Every organization can simplify and streamline its activities with an effervescence of excellence with an oil & gas ERP solution under the aegis of SAP S/4HANA solutions.

Features of SAP in Oil & Gas Industry

- Financial data on product sales and purchases, as well as other industrial requirements, are meticulously updated in a system so that cash flow management processing is simple.

- An organization’s inventories are managed efficiently, allowing for easy stock reconciliation tracking.

- Budgeting is done in accordance with the projected production schedule in order to deliver high-quality items that offer value to your company.

- In order to manage production planning, efficient handling of functional modules analyses raw resources necessary.

- In the oil and gas industries, where the automated process leads to a rise in revenue, a business intelligence tool makes project management more successful.

- The SAP software solution is cost-effective, and it is best suited for small and large-scale businesses looking to compete.

- To access information at any time, an integrated enterprise software solution does not require technical expertise.

Why safety is important in Oil & Gas Industry?

The oil & gas industry, which is potentially one of the most dangerous, has one of the most comprehensive safety measures. The combination of powerful machinery, volatile chemicals, and high-pressure procedures can result in dangerous and even fatal catastrophes. That’s why it’s critical for safety managers and supervisors to identify and communicate appropriate safety controls and dangers before work begins on each job site.

These factors can have an impact on worker safety by increasing human error, such as equipment abuse and inconsistent practices, which can lead to an increased risk of accidents. Apply these tips to improve worker safety on your next project:

1. Collaborate with the Local Emergency Response Community

To ensure a higher level of overall safety, develop a partnership with local emergency response organizations and build a continuous flow of communication. Emergency responders, rig workers, and exploration firm safety and health professionals must collaborate to maximize their resources in order to respond to incidents quickly and effectively. Discuss the unique health and safety hazards present at the drilling site and how to best support one another in these situations.

2. Actively Monitor Mental Health of Workers

Workplace culture is a major issue that has a detrimental impact on workplace safety. By establishing a transparent and open environment through various training strategies and team exercises, you may eliminate the age-old “tough guy” façade and stereotype that is generally associated with workers in the business. Building a sense of community and trust among employees will encourage them to ask for help, follow regulations, admit mistakes, and seek to advice, resulting in a more happy and safe workplace.

3. Consistent Housekeeping

To avoid accidents falls, and struck-by dangers, maintain floors, paths, and other work areas clean of needless materials. To immediately battle dangers, use unambiguous signage that guides workers to emergency and safety equipment. For example, in the event of a chemical or oil spill, provide spill kits to all problem areas.

4. Install an In-Vehicle Monitoring System (IVMS)

The oil and gas industry has the largest number of total fatalities due to accidents involving driving or riding in a motor vehicle. Monitor driver behavior to identify problems and bad behaviors so you can enhance your vehicle safety initiatives and employee training.

5. Reassess Safety Signage When Projects Shift

When worksites, projects, and crews change, make sure that signs and labels are in the right places and that current hazards and procedures are communicated before the next project begins; this will guarantee that new workers are aware of dangers and specifics about specific locations.

6. Provide Clear Visual Communication

To communicate threats and safety requirements, use readable and dependable signs and labels to minimize miscommunication and confusion. Make personalized signs to communicate procedures unique to specific work crews and job sites. As soon as feasible, replace worn-out, unreadable, and outdated signage.

7. Implement a 5S System

A 5S system can help you improve your workflow and eliminate waste. To direct, warn, and transmit a range of different facts to workers, use strategic labeling approaches. Color-code materials in the workplace to make finding specific tools, equipment, and other items easier and faster.

8. Invest in a Safety Program that Unites Workers

Encourage an atmosphere of open dialogue and mutual respect. Adopt a personalized approach to safety training and set aside time for employees to get to know one another. When out in the field, making more meaningful personal ties with coworkers can organically increase trust and comradery, improving overall safety.

9. Ensure Familiarity with Worksites

Before starting work, make sure everyone involved is aware of their responsibilities, potential hazards, and safety procedures. In the event of shift handovers or work site changes, require that all procedures and dangers be thoroughly conveyed to new workers.

10. Stay On Top of Machine Maintenance

When operating on offshore rigs hundreds of miles from shore, the machines are your lifeline. Regular maintenance checks of machinery can help you avoid premature machine failure and keep your personnel safe.

Which SAP module is best for the oil and gas industry?

The SAP module that is best suited for the oil and gas industry is the SAP Oil & Gas (SAP O&G) solution. This industry-specific module is designed to address the unique challenges and requirements of companies in the oil and gas sector. SAP O&G provides comprehensive functionalities to support various aspects of the industry’s operations, including exploration, production, refining, distribution, and retailing.

Key features of the SAP Oil & Gas module include:

- Upstream Operations: Managing exploration, drilling, production, and reserves management.

- Downstream Operations: Covering refining, storage, transportation, and marketing of petroleum products.

- Joint Venture Accounting: Handling financials and accounting for joint venture partnerships common in the oil and gas industry.

- Commodity Management: Managing the trading and risk management of commodities.

- Plant Maintenance: Enabling efficient maintenance and asset management for equipment like drilling rigs, pipelines, and refineries.

- Supply Chain Management: Optimizing the supply chain to ensure smooth production and distribution.

- Health, Safety, and Environment (HSE): Addressing health and safety regulations and environmental compliance.

- Asset Lifecycle Management: Handling the entire lifecycle of assets, from acquisition to decommissioning.

By utilizing the SAP Oil & Gas module, companies in the oil and gas industry can enhance their operational efficiency, improve decision-making, and streamline their business processes to stay competitive in a challenging and dynamic market. However, it’s essential for organizations to conduct a thorough evaluation of their specific requirements and consult with SAP experts to ensure the best fit for their unique business needs.