Introduction

The drive for functional effectiveness in assembling and retail has heightened as enterprises are progressively tested by rising client assumptions, advancing advancements, and worldwide rivalry. From the production line floor to the retail location, organizations are utilizing computerized change apparatuses, for example, undertaking asset arranging (ERP) frameworks, Web of Things (IoT), and progressed examination, to upgrade their tasks, lessen costs, and further develop consumer loyalty.

In both assembling and retail, functional effectiveness isn’t just about reducing expenses — it’s tied in with upgrading work processes, improving item quality, further developing store network the executives, and giving a remarkable client experience. This blog will investigate certifiable use cases that feature how organizations in these areas can use innovation to accomplish improved functional productivity.

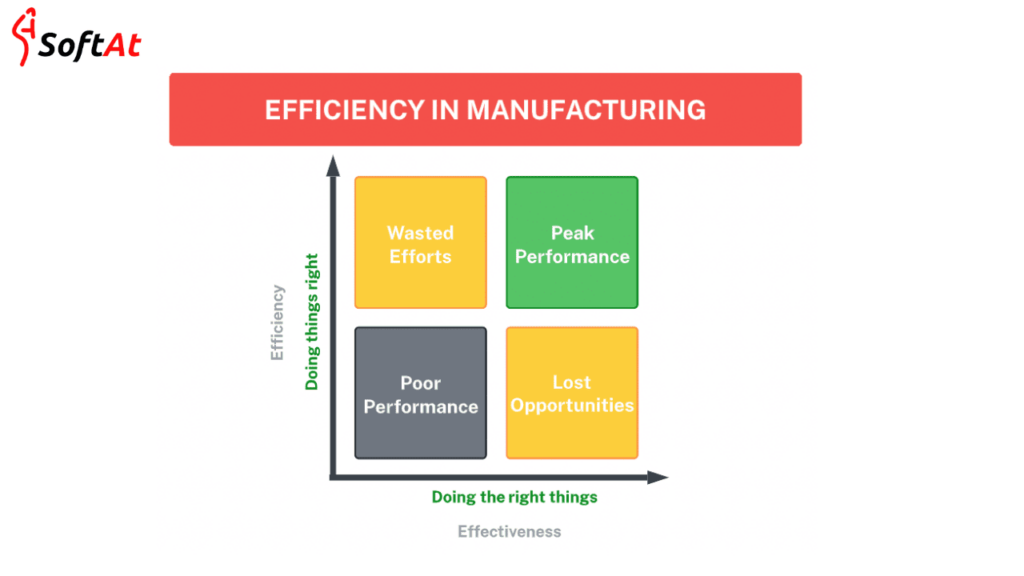

1. Operational Efficiency in Manufacturing

In assembling, functional proficiency spins around boosting throughput, limiting margin time, decreasing waste, and guaranteeing steady quality — all while keeping up with wellbeing guidelines. The execution of cutting edge innovations is assisting makers with enhancing different parts of creation, from natural substance obtainment to end result conveyance.

1.1. Predictive Maintenance

- One of the most significant use cases for functional effectiveness in assembling is prescient support. By coordinating IoT sensors into apparatus and creation hardware, makers can gather continuous information on the state of their resources. This information is handled and examined to foresee possible disappointments before they occur, permitting organizations to do support exercises at the ideal time.

- For instance, an auto producer could utilize IoT sensors implanted in machines to screen vibrations, temperature, and execution. Prescient support models controlled by AI (ML) can then dissect this information to foresee when parts might break down. By performing upkeep proactively, makers can decrease spontaneous personal time, keep away from exorbitant fixes, and work on the general life expectancy of their gear.

- SAP S/4HANA and SAP Prescient Upkeep are prime devices in this cycle, assisting associations with foreseeing disappointments, smooth out upkeep plans, and lessen functional disturbances. Subsequently, makers experience further developed efficiency, diminished working expenses, and more proficient asset use.

1.2. Supply Chain Optimization

- Makers depend on store network the board (SCM) to source unrefined substances, oversee stock, and convey completed items. In any case, shortcomings in the production network can essentially affect functional execution. This is where information driven arrangements assume an essential part.

- By incorporating constant examination into their stockpile chains, producers can enhance stock levels, diminish lead times, and guarantee opportune conveyances. Utilizing cloud-based ERP frameworks like SAP Coordinated Business Arranging (IBP), producers can acquire continuous perceivability into their production network exercises and settle on information driven choices.

- For example, a customer gadgets organization can follow stock across various distribution centers, comprehend request examples, and make constant changes in accordance with their obtainment and creation plans. This lessens stockouts and overabundance stock, which prompts lower functional expenses, further developed income, and expanded consumer loyalty.

1.3. Smart Factories and Automation

- One more groundbreaking pattern in assembling is the reception of brilliant plants fueled by Industry 4.0 advancements. These processing plants incorporate computerization, IoT, large information, and man-made reasoning (simulated intelligence) to upgrade creation productivity. Mechanical technology and robotized directed vehicles (AGVs) are progressively being conveyed to smooth out processes, while ongoing observing permits makers to screen creation status and immediately distinguish bottlenecks.

- For instance, a food handling plant could carry out mechanical arms to mechanize the bundling system. These robots are associated with the industrial facility’s focal framework, which utilizes continuous information to change creation rates in view of stock levels and request estimates. SAP Assembling Execution Framework (MES) deals with this incorporation by furnishing producers with constant following, quality confirmation, and perceivability into processing plant execution.

- The outcome is a huge lift in throughput, improved item consistency, less human blunders, and the capacity to rapidly adjust to changing economic situations.

1.4. Energy Management and Sustainability

- Energy utilization is a huge expense in assembling, and there is a developing spotlight on diminishing energy use to further develop maintainability and lower costs. IoT sensors and progressed examination are assisting producers with enhancing energy utilization across their tasks.

- For instance, a material producer could involve IoT-empowered shrewd meters to screen energy utilization continuously across machines, lighting, and central air frameworks. SAP Climate, Wellbeing, and Security (EH&S) can give the essential apparatuses to follow energy utilization, put forth energy-saving objectives, and make covers supportability execution.

- By changing machine activity plans, upgrading warming and cooling frameworks, and recognizing energy squander, producers can diminish their carbon impression while improving their functional proficiency.

2. Operational Efficiency in Retail

In retail, functional proficiency is tied in with further developing production network perceivability, smoothing out stock administration, decreasing expenses, and giving an excellent client experience. Retailers are utilizing innovation to meet customer assumptions for quicker administration, customized encounters, and predictable item accessibility.

2.1. Real-Time Inventory Management

- One of the significant difficulties in retail is guaranteeing that items are accessible when clients need them. Stock administration is key to accomplishing functional productivity, and continuous following assumes a basic part in streamlining stock levels and forestalling unavailable situations.

- For example, a design retailer can utilize RFID labels and IoT sensors to follow item development from the distribution center to the store floor continuously. By coordinating this information with their SAP ERP framework, retailers can acquire continuous perceivability into stock levels across various areas, consequently reorder items when stock is low, and advance stock turnover.

- Furthermore, SAP Coordinated Business Arranging (IBP) permits retailers to figure interest and change acquirement methodologies in light of constant deals information, guaranteeing that stock levels are constantly lined up with client interest, prompting further developed effectiveness and consumer loyalty.

2.2. Personalized Customer Experience

- Personalization is turning into a vital differentiator in retail. By utilizing information examination and client bits of knowledge, retailers can convey customized suggestions, offers, and encounters that drive client commitment and deals.

- For instance, a supermarket chain can utilize client buying information from reliability projects to suggest customized limits or advancements in light of individual inclinations and purchasing propensities. By incorporating client information with SAP’s Client Experience (CX) suite, retailers can make designated promoting efforts that advance change rates and further develop client maintenance.

- This information driven approach further develops the client experience, assists retailers with adjusting items to customer interest, and improves functional proficiency by zeroing in on high-esteem exchanges.

2.3. Omnichannel Retailing

- Omnichannel retailing has become fundamental for organizations hoping to further develop proficiency and draw in with clients across numerous touchpoints, whether on the web, coming up, or by means of versatile. Flawlessly coordinating Web based business stages with actual stores, retailers can smooth out request satisfaction and decrease functional expenses.

- For instance, a worldwide retailer could execute a framework that permits clients to purchase on the web and get coming up (BOPIS). This demands constant joining between SAP Business Cloud and the in-store stock framework. Clients can actually look at item accessibility continuously, and the retailer can satisfy the request all the more productively, saving money on transportation costs and further developing conveyance times.

- By giving a consistent shopping experience across channels, retailers upgrade functional productivity, increment consumer loyalty, and diminish strategic difficulties.

2.4. Supply Chain Transparency and Traceability

- Retailers face huge difficulties with regards to store network straightforwardness, particularly in guaranteeing that items are morally obtained and conform to administrative prerequisites. Blockchain and IoT advances are assisting with expanding discernibility and straightforwardness across the retail production network.

- For example, an extravagance style retailer might utilize blockchain innovation coordinated with SAP answers for follow the beginning of materials utilized in their items. Clients can examine an item’s QR code to see its excursion from the maker to the retail location. This degree of straightforwardness works on functional proficiency by diminishing the gamble of extortion, guaranteeing item quality, and improving brand trust.

- By improving store network discernibility, retailers can more readily oversee provider connections, guarantee consistence with manageability drives, and moderate inventory network interruptions

3. Common Technologies Driving Operational Efficiency

A few key advancements are assuming a critical part in improving functional proficiency in both assembling and retail:

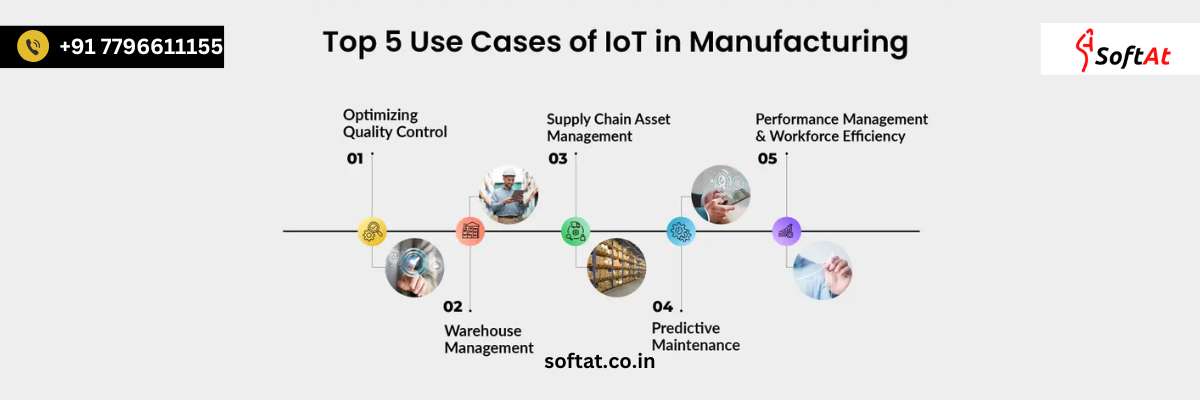

3.1. Internet of Things (IoT)

- IoT is an extraordinary innovation that interfaces gadgets, hardware, and sensors to gather and share information. In both assembling and retail, IoT empowers ongoing checking, robotization, prescient support, and information driven direction.

3.2. Artificial Intelligence (AI) and Machine Learning (ML)

- Simulated intelligence and ML are assisting organizations with anticipating patterns, upgrade processes, and further develop client encounters. In assembling, they power prescient upkeep models, while in retail, they improve stock administration and personalization systems.

3.3. Cloud Computing and ERP Systems

- Cloud-based ERP frameworks, like SAP S/4HANA, give producers and retailers constant perceivability into activities, robotize work processes, and enhance asset the executives. Distributed computing additionally upholds adaptability and diminishes the requirement for on-premises framework.

3.4. Automation and Robotics

- From savvy stockrooms to robotized creation lines, mechanization is reforming functional proficiency. Mechanical technology, artificial intelligence controlled frameworks, and robotized directed vehicles (AGVs) smooth out processes, decrease human mistake, and increment throughput in assembling and retail conditions.

Conclusion

- In both assembling and retail, accomplishing functional effectiveness is vital to remaining serious and meeting client assumptions. By utilizing cutting edge innovations like IoT, artificial intelligence, prescient investigation, and cloud-based ERP frameworks, organizations can upgrade creation processes, further develop store network the executives, lessen waste, and improve consumer loyalty.

- As we’ve found in the utilization cases featured above, producers and retailers that embrace advanced change and innovation development can smooth out activities, lessen costs, and give unrivaled client encounters. For those hoping to upgrade functional effectiveness, the way ahead lies in utilizing information, mechanization, and coordinated frameworks to drive constant improvement and business development.

You may be interested in:

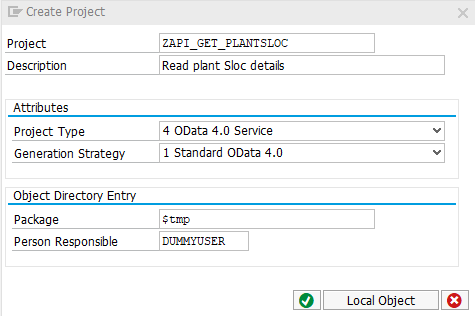

A Deep Dive into SAP API Management

Integration cloud system to HANA Cloud Platform using Cloud Connector