What is SAP Manufacturing?

SAP Manufacturing solutions enable your company to integrate and embed intelligence in processes facilitating Industry 4.0 principles with a single source of real-time information. They provide the data required for optimal coordination of resource planning and production execution, covering all aspects of the manufacturing cycle from production order to order fulfillment and beyond. Digitization of your manufacturing processes allows you to increase manufacturing efficiency and agility and leverage the Industrial Internet of Things (IIoT). Furthermore ensures transparency at the component and material level at all times. How is SAP used in manufacturing?

SAP is the only company that provides a fully integrated solution from machine level to ERP all-in-one. If your company is already running on SAP S/4 HANA and you are looking to fully integrate your supply chain and get more out of your production, SAP offers a variety of solutions for digital manufacturing.

Digital Manufacturing with the SAP Manufacturing Suite

The modular structure of the SAP Manufacturing Suite powered by SAP Leonardo allows you to scale a solution tailored towards your specific needs. Whether your needs range from basic MES functionality with a focus on effectively controlling work-in-progress (WIP) processes, to “paperless manufacturing” by automating communication and decision-making regarding the execution of production processes, to more advanced automation capabilities where the operator oversees production processes which execute through limited or no human intervention – it is possible to identify the modules, methods, and products necessary to meet the unique needs of your production environment.

- SAP Manufacturing Execution (SAP ME)

SAP ME is a complete, configurable MES system for discrete manufacturing that enables you to manage and control production operations. - SAP Manufacturing Integration and Intelligence (SAP MII)

SAP MII is the proven solution for the process industry. In addition to being able to monitor production in near real-time, it offers extensive data analysis tools. Data from a wide range of systems can be integrated, and combined with data from business systems and necessary actions can be executed automatically or manually. - SYSTEMA’s SAP Accelerator Suite (MAX Suite)

SYSTEMA’s Accelerator Suite is a rapidly deployable, modular solution that can be quickly implemented to provide MES-like services. - SAP Plant Connectivity (SAP PCo)

SAP PCo enables data transfer between the production levels with SAP Execution Systems (MES) and ERP. - SAP Digital Manufacturing Cloud (DMC)

SAP DMC, improves with near real-time data and analytics. Execute manufacturing processes, analyze manufacturing and business data, and integrate systems with a cost-effective, high-quality, and resource-efficient method based on Industry 4.0. - SAP HANA Cockpit

SAP HANA Cockpit ensures IT systems’ availability and optimizes computing power. - SAP OEE Package Solutions

Overall equipment effectiveness (OEE) measures the true performance of manufacturing productivity by evaluating equipment availability, production performance, and product quality factors.

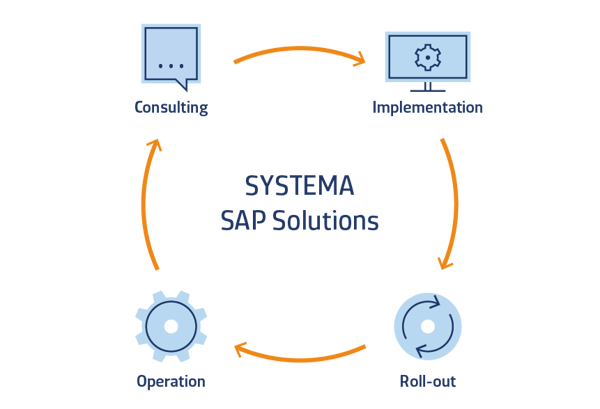

SAP Manufacturing Consulting and Services

- Analysis and optimization of manufacturing processes

- Architecture and process consulting for manufacturing execution solutions

- Design and implementation of automation solutions

- Integration of standard SAP MES solutions

- Customized extensions for SAP MES solutions

- Equipment integration services (more than 10,000 equipment integrations worldwide)

- Execution of international projects from small to large scale

- Support for SAP MES implementations with 24/7 support operating 365 days a year

SAP ERP FOR THE MANUFACTURING INDUSTRY

Technology is advancing rapidly, and forward-thinking manufacturers are embracing the digital revolution. SAP ERP For Manufacturing Industry They are adopting new technologies in order to stay relevant, innovative and competitive. One of these important technologies is the use of SAP erps for the manufacturing industry.

All manufacturers strive to optimize their operational processes by reducing costs, improving efficiency and increasing profits. Advancements in technology have aided many manufacturers in achieving these goals.

Failure to adopt new technologies in your manufacturing business will make it significantly harder for it to thrive and grow in today’s fast-paced, digital business environment.

SAP ERP

SAP was founded in 1972 by five former IBM engineers, and is one of the largest global vendors of Enterprise Resource Planning (ERP) software.

It offers industry-specific ERP solutions that support business processes across procurement, manufacturing, service, sales, finance, and human resources.

SAP ERP solutions support the following manufacturing types:

- Discrete Manufacturing: A manufacturing process whereby finished products are distinct items capable of being easily counted, touched, or seen. Discrete manufacturing involves parts like nuts and bolts, brackets, wires, and individual products. Examples of products made by discrete manufacturing include furniture, toys, and smartphones.

- Process Manufacturing: A process whereby a product is created by using a formula or recipe to refine the raw ingredients. The final product cannot be broken down into its basic components. Examples of products made by process manufacturing include pharmaceuticals, paint, food and beverages.

- Repetitive Manufacturing: In this process, goods are manufactured by following the same production sequences. This type of manufacturing process often goes hand-in-hand with automated assembly processes. Examples of products made by repetitive manufacturing include small electronic goods and car components.

SAP ERP Integrations

SAP ERP solutions integrate with the following systems:

- Salesforce

- Microsoft Dynamics

- Zoho CRM

- Oracle

- Sage

- NetSuite

SAP ERP’s for the Manufacturing Industry

SAP Business One

Designed for small and mid-size businesses, SAP Business One is an ERP solution that automates and streamlines key business functions in financials, operations, and human resources. With SAP Business One, you will gain greater insight into your business, streamline key processes and make strategic decisions based on real-time information. SAP Business One can be deployed on the cloud or on-premise and is integrated with business intelligence and the SAP HANA platform.

Key Features of SAP Business One

- Financial management

- Sales and customer management

- Purchasing and inventory control

- Manufacturing management

- Inventory management

- Industry-specific manufacturing capabilities

Manufacturing sectors involved in the production of new products from seized raw materials are in need of software to leverage their in-and-out operations. SAP software solution adopted by manufacturing industries automates the complete process to attain successful production. It provides a single scalable approach to attain a profitable position.

Varied functionalities like the production process, inventory management, financial module, the requirement of raw materials, etc are covered under an integrated platform scrutinizing the production process to give out effective outcomes. An automated system gives a complete solution in order to avail fast growth.

How Does ERP Help in Manufacturing?

ERP helps in manufacturing to automate the business processes from sales orders to finished goods. It manages inventory, controls production, provides orders and demand, and gives end-to-end visibility into the production process.

When talking with executive managers from manufacturing companies, we consistently hear the same business needs they expect from manufacturing ERP software:

Manage Inventory and Bills of Material for Manufacturing

- Handle all types of bills of materials, and multi-level bills of materials

- Incorporate landed costs for material coming from overseas

- Record, track, and produce serial and/or batch numbers for incoming and outgoing products

- Manage multiple units of measure

- Conduct materials planning, purchasing, and inventory forecasting projections within MRP

Manage the Production Process

- Manage production orders electronically

- Generate either an assembly or disassembly work order

- Record the usage of raw materials, resources, and labor

- Generate finished goods

As a manufacturer grows, the business expands and drives additional needs or requirements. To speed warehouse operations they look for wireless, handheld devices that are integrated into inventory systems for use in the warehouse. To facilitate vendor orders and payments, they look for integration with EDI tools. To expedite outbound shipping they look for integration with major shipping service providers like UPS, FedEx and USPS. We have also seen requirements for advanced production scheduling, shop floor control, batch/lot management, WIP management, and job costing.

The process to help you compare SAP ERP manufacturing solutions starts with understanding your place in the market now, and your vision for the future. We ask questions to understand your business size, manufacturing process, place within your industry, and where you want your business to be. Then we match your requirements, functions, users, and investment goals to the SAP solution set to select an appropriate platform.

We apply your business principles with those we have encountered across our customer base. SoftAt Private Limited has experience with providing ERP solutions within a number of manufacturing verticals, including automotive, chemicals, electronics, fabricated metals, food, furniture, lighting, machinery and equipment, and consumer goods just to name a few.

- SAP is considered to be a soulful software package covering all business entities within a single software package.

- Data about the utilization of resources are recorded inducing to analyze the demand for raw materials with ease.

- Accounts payable and receivable are maintained effortlessly by a valid financial management system since it gathers reports from every module.

- Daily production details are recorded enabling effective planning on a diversified process inconsistent manner.

- Efficient maintenance of inventories tracks the supply chain of furnished products allowing to generate of demand-based production.

- The integrated solution promotes delivering quality products to customers. Pre-checking functionality exists before a product is delivered to an ordered person.

- Documents on overall processing are retained under a separate cloud database. The information available can be viewed by concerned organizational authorities whenever in need of it.

- Customer relationships are greatly enhanced through the SAP software package. Queries and ordering of consumers are responded to quickly by sales representatives provoke to engage in long term business deals.

- SAP software takes care of end-to-end processing in an automated approach avoiding disruptions from production to sales of finished products.

- It reduces time and amount spent in the manufacturing of varied products by skillful planning since it gets linked with every module.

- Software system supports for efficient implementation of resources and labor based on which firm process is done in the regulatory process.

- Feedback collected from customers helps manufacturers to upgrade areas of improvement. By doing so, the meeting of target people gets enriched.

- Records on entire functionalities maintained in a secured mechanism do not allow for third-party intruders to access information.

What are SAP modules for manufacturing?

SAP offers several modules that cater to the needs of the manufacturing industry. These modules are designed to help streamline various manufacturing processes, manage production operations, and improve overall efficiency. Some of the key SAP modules for manufacturing include:

- SAP Production Planning (PP): SAP PP module handles the entire production process, including material requirements planning, capacity planning, production order management, and scheduling. It enables manufacturers to plan and execute their production activities effectively.

- SAP Material Management (MM): While not exclusively a manufacturing module, SAP MM plays a crucial role in the manufacturing process. It manages procurement, inventory, and warehouse processes, ensuring the availability of required raw materials for production.

- SAP Plant Maintenance (PM): The SAP PM module assists manufacturers in managing the maintenance of their production facilities and equipment. It helps in planning and executing preventive and corrective maintenance tasks.

- SAP Quality Management (QM): SAP QM module is responsible for quality control and assurance in manufacturing. It covers quality planning, inspection, and reporting to ensure that products meet the required standards.

- SAP Advanced Planning and Optimization (APO): APO is an advanced planning module that includes functionalities like demand planning, supply network planning, and production planning and detailed scheduling (PP/DS). It helps in optimizing the entire supply chain and manufacturing processes.

- SAP Extended Warehouse Management (EWM): While primarily focused on warehousing, EWM is essential for manufacturing companies that require advanced warehouse management capabilities, especially for complex logistics and distribution scenarios.

- SAP Manufacturing Execution (ME): This module supports shop floor operations, including order processing, real-time production monitoring, and tracking, as well as capturing production data for analysis and reporting.

- SAP Product Lifecycle Management (PLM): SAP PLM helps manage the entire lifecycle of products, from design and development to manufacturing, maintenance, and disposal. It facilitates collaboration among different teams involved in the product lifecycle.

- SAP Variant Configuration (VC): VC allows manufacturers to configure complex products with various options and variants, enabling flexible production and customization.

- SAP Overall Equipment Effectiveness (OEE): This module measures the efficiency of equipment and manufacturing processes, helping manufacturers identify areas for improvement and optimization.

It’s important to note that SAP’s product offerings may evolve over time, and some modules may be combined or rebranded under different names. Therefore, it’s advisable to check with SAP or an SAP implementation partner to get the most up-to-date information on the specific modules available for the manufacturing industry.